charpy impact testing harsh conditions|charpy impact cheat sheet : agencies Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Resultado da Compre pela internet no Supermercado Koch sem sair de casa. Entrega ou Retirada. Hortifruti, carnes, congelados, higiene, limpeza, padaria, bebidas e muito mais. Confira as ofertas da semana. Satisfazer pessoas e proporcionar consumo a preço justo.

{plog:ftitle_list}

WEBMariana Ximenes nude - Eu Que Amo Tanto. 206.1K views. 06:24. Anya’s Ts Cam Show. 14.5K views. 06:08. Mariana Ximenes Beautiful Brazilian Actress. 77K views. Related Pornstars. julianandsarah95. 466 #16497. Porscher Wells. 499 blueemotion89. 2K GG Katie .

charpy impact testing procedure

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .According to the standard test methods, the Charpy or Izod impact test can be employed to investigate the behavior of specified types of specimens under the impact conditions defined . Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to .

This paper presents the results of the Charpy V-Notch (CVN) impact test for the ST, TL, TS, LS, LT, 45°, and SL directions in API 5L X52 pipelines with electric-resistance-welded (ERW) and .

Charpy Impact Testing. The Charpy Impact test is a method used to assess the impact toughness of metals and alloys. This test is commonly employed to evaluate the susceptibility of materials to sudden impact and measures the energy absorbed. . Oil & Gas: Essential for ensuring the integrity of fasteners in the Oil & Gas sector, where extreme . The Charpy impact test interpretation is much more complex than the test itself when compared to other tests such as fracture toughness or Pellini drop weight tests. . details on these materials and test conditions are not available to further investigate this outlier behavior. Download: Download high-res image (162KB) Download: Download full .

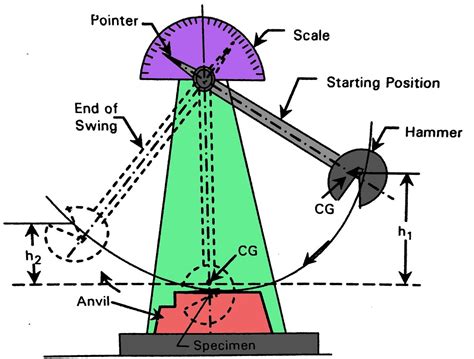

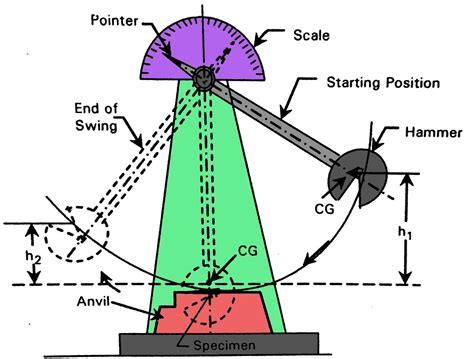

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, . Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined piece of metal cooled to the required temperature to measure the amount of fracture at that temperature.

Robust and impact-resistant materials are deemed mandatory concerning the harsh operational conditions where these UAVs are employed. . The Charpy impact test results can only be used as comparative data to assess the impact energy absorption of different materials, although standard exempts it for design purposes. . specimen integrity .Part 2: Verification of the testing machine (pendulum impact). (1993). This European standard specifies the impact test according to Charpy (U- and V-notch) for determining the impact strength of metallic materials. For certain special metals and applications the Charpy impact test may be subjected to specific standards or special regulations. 2.

charpy impact testing methods

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.EN10045 regulates the Charpy impact testing method, a widely used technique for assessing materials' toughness and impact resistance. Developed by CEN, this standard outlines guidelines and specifications for Charpy impact tests. . It signifies the machine's ability to withstand heavy usage and harsh testing conditions without compromising . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Charpy V-Notch (CVN) Impact Test. The CVN impact test is required for many PSL2 pipe sizes and grades. This test measures the pipe’s ability to absorb energy and resist fracture, ensuring its performance in extreme conditions. The CVN impact test helps to ensure that the pipes can withstand the harsh conditions encountered in many pipeline .

Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for .

Steel used to construct wind turbines must undergo testing to ensure that it can endure harsh conditions. The Charpy Impact Test, also known as the Charpy V-Notch Test, is the standardized test done on steel used for wind turbines. The Charpy Impact Test measures a material's ability to absorb energy, or impact, within a given temperature range. The fracture properties and susceptibility to crack-divider delamination (or splitting) of three commercially produced high-toughness X70 pipeline steels are evaluated with Charpy impact test . Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed . The Charpy Impact Test is widely regarded for its ability to simulate real-world conditions, making it a fundamental procedure in material testing. Understanding the Impact Test. To understand the Charpy Impact Test comprehensively, it is important to focus on its procedure, test parameters, and interpretation of results.

The influence on the Charpy V-notch impact behaviour in the transition region is investigated taking into consideration the residual stresses, work hardening and the surface topology at the notch root caused by manufacturing. Three materials were made available for the investigation, an unalloyed structural steel in the normalised and in the partially austenitised . An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer.

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on .A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . The Charpy impact test is one of the most widely used techniques for evaluating the impact toughness of metallic materials. This test is based on measuring the energy absorbed by a material during fracture caused by a sudden impact, simulating real stress conditions that could cause a metal component to fracture.

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

Download scientific diagram | Charpy impact test criteria for 316 L(N) stainless steel: originally based (RCC-MR Code) on Charpy U specimen tests, but from now on Charpy V specimen. from .

DAFTAR. LIVE CHAT. LOGIN. WHATSAPP. TIGER77 - Login, Daftar, Livechat, Whatsapp & Link Alternatif Untuk Member Melakukan Deposit Withdraw Dan Melihat Promosi Bonus Dengan Customer Service 24jam.

charpy impact testing harsh conditions|charpy impact cheat sheet